Additive Manufacturing | Textiles

No Poking Metals

2023

The "No Poking Metals" dress replaces rigid wires with 3D-printed, flexible structures, combining comfort and elegance through innovative fabrication techniques

Metal wires have long been a staple in creating intricate, eye-catching designs for garments, especially in couture and avant-garde fashion. However, while they allow for stunning shapes and structures, they often come at a cost—comfort. There’s nothing worse than metal poking into your skin, restricting movement. The very material meant to enhance the beauty of the design ends up detracting from the experience of wearing it.

No Poking Metals reimagines the way garments achieve structure and design. The goal of this project was to demonstrate how fashion can evolve to prioritize both aesthetics and comfort without compromise. By replacing traditional metal support structures with 3D-printed, mesh-integrated designs, the project aimed to create garments that are visually intricate, structurally sound, and comfortable to wear. This innovative approach bridges the gap between artistry and technology, redefining what is possible in wearable design.

The use of 3D printing also allows the structures to match the design and color of the fabric, making them nearly invisible while maintaining functionality. This approach not only solves practical challenges but also opens new possibilities for wearable technology that prioritizes both beauty and wearability.

The process began with hand-drawn designs of the fabric, carefully planning out the details and patterns needed for both visual appeal and structural support. These designs were then translated into CAD models to create additional supports that would reinforce the garment while maintaining its flexibility and comfort.

The fabrication process involved a multi-step 3D printing technique. Four layers of PLA were printed initially to provide a sturdy base, followed by the addition of a mesh layer mid-print. This mesh was carefully embedded to act as a flexible intermediary between the rigid PLA and the fabric. The print was then completed by layering more PLA on top, securing the mesh within the structure.

Once completed, the mesh-embedded print was placed beneath the final fabric, aligning with the hand-drawn design. This integration ensured that the 3D-printed structures remained visually unobtrusive while providing essential support for the garment's shape and form. The result is a revolutionary approach to wearable design that eliminates the discomfort of traditional metal supports, offering both elegance and practicality. This project demonstrates how fashion can evolve to prioritize both aesthetics and comfort without compromise.

Photo by Joey Castillo

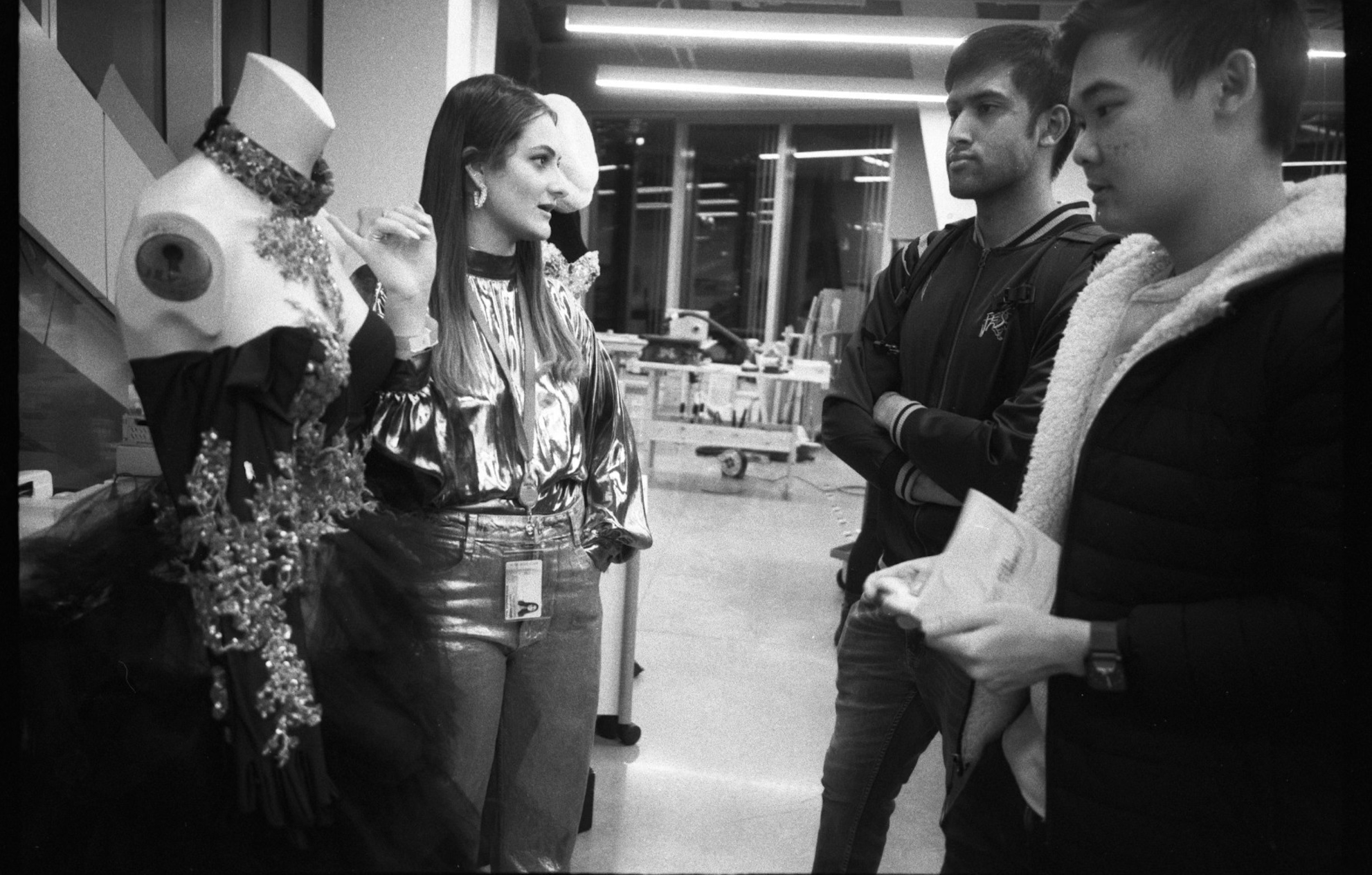

This project was part of the Cornell Tech’s Open Studio 2023, where students, faculty, and community partners showcase what they have accomplished this year.

This is the making of No Poking Metals.

Photos by Niti Parikh at Cornell Tech Maker Space

Photos at the Cornell Tech Winter Formal

SPECIAL THANKS

Niti Parikh

Sebastian Bidegain

Cornell Tech MakerLAB

Director MakerLAB

Lab Manager